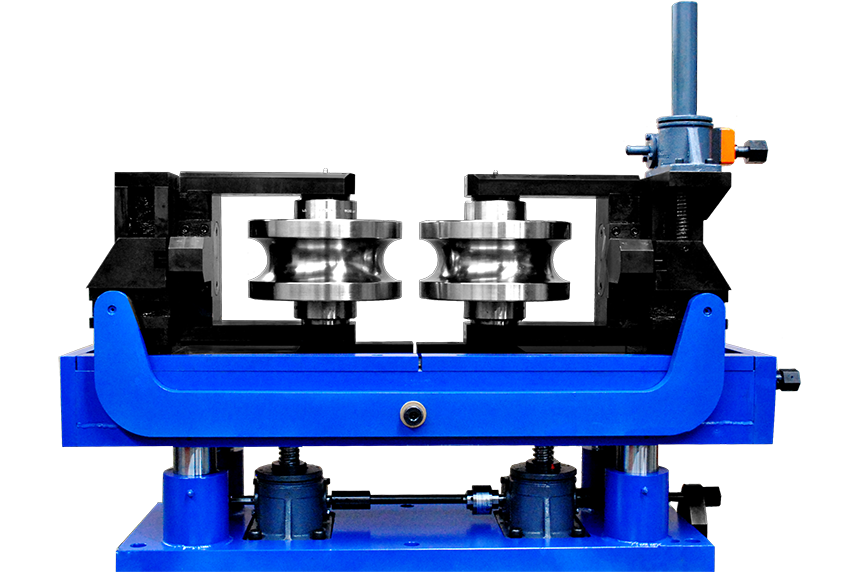

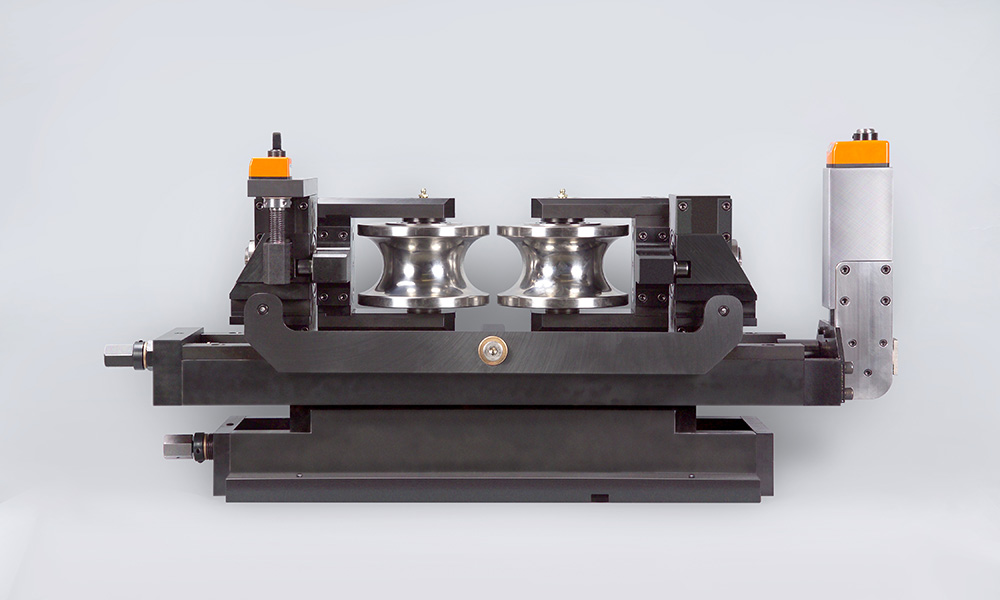

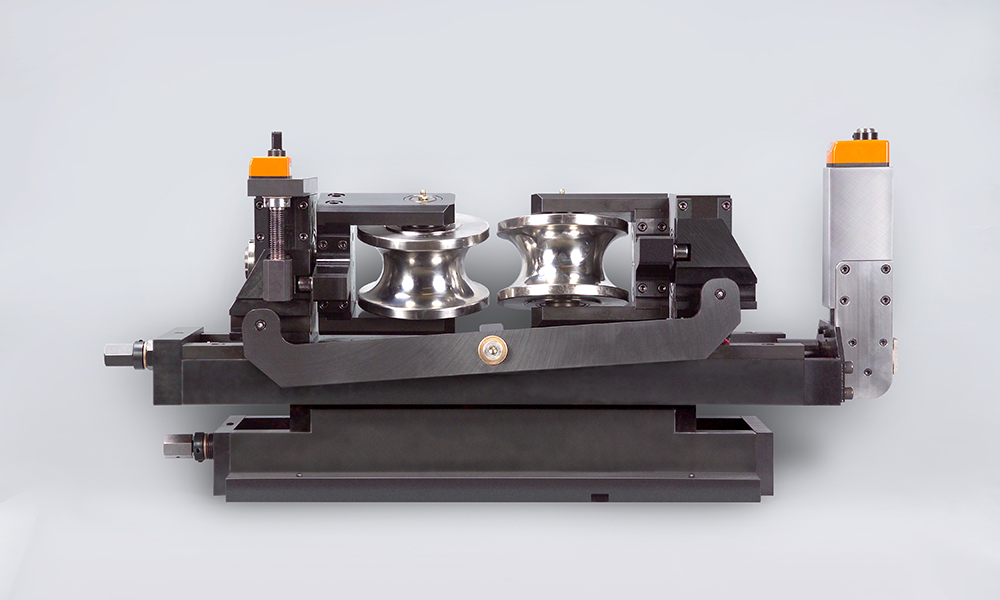

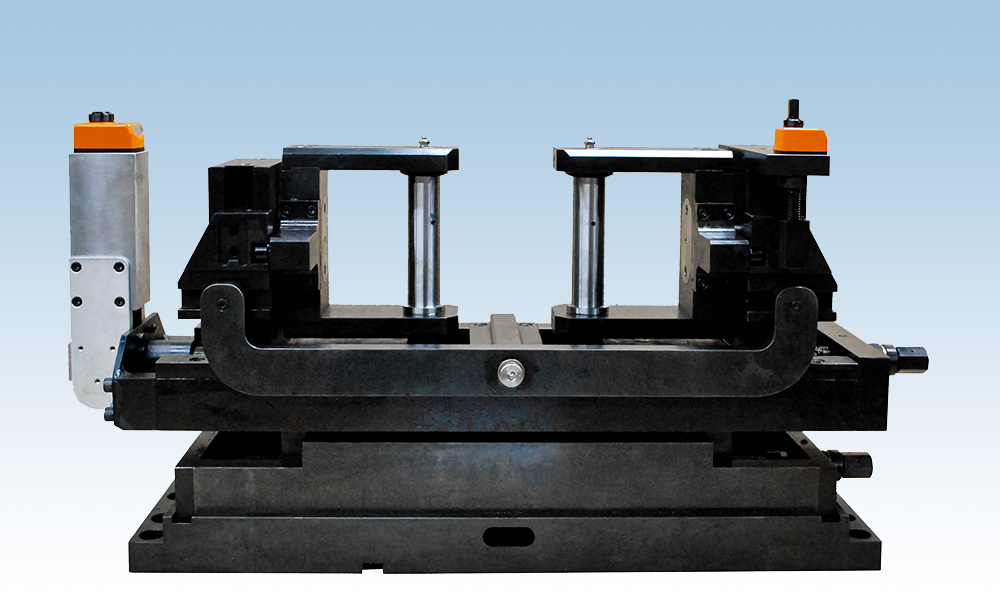

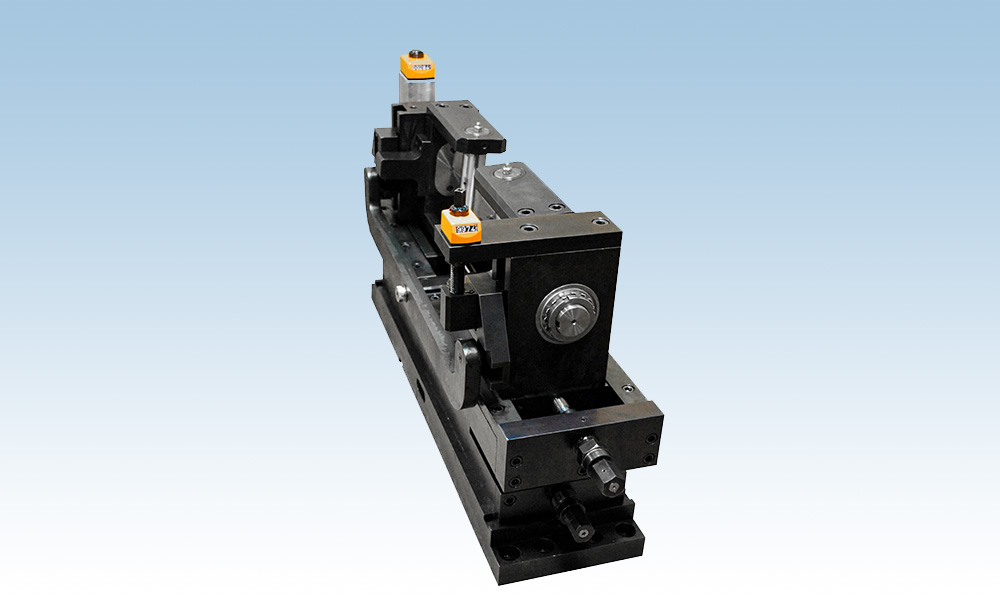

Seam Orientation Units for Tube Mills

Our Seam Orientation Unit is designed to locate the weld seam in any location on the tube between the 10 o'clock and the 2 o'clock position.

The seam orientation stand is located after the induction welding section to maintain the weld seam at top, dead center to insure proper annealing of the tube and pipe weld seam. Likewise, when forming shapes from a round tube or pipe, the seam orientation stand can maintain the weld seam at top, dead center during the shaping process.