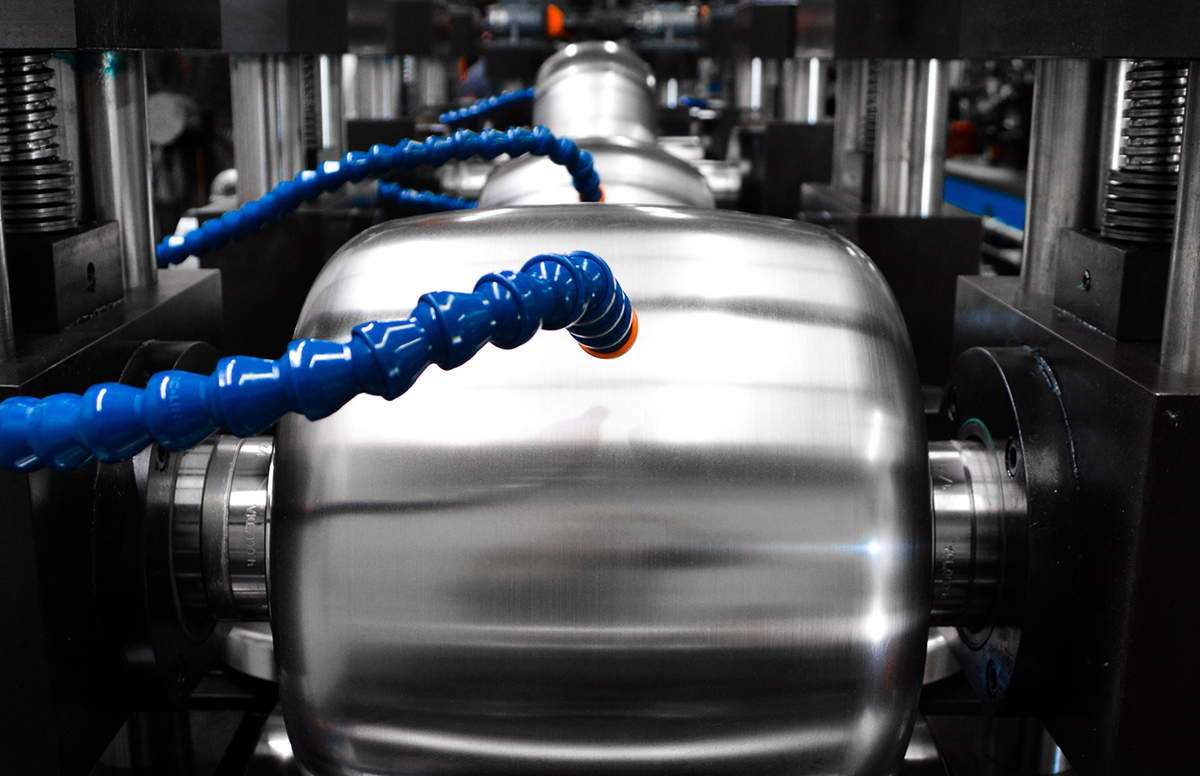

We offer complete tube mill production solutions for high-frequency welding applications, custom engineered and designed to match your production requirements. We partner with producers to manufacture production lines for your existing and for new tubing sizes and materials.

Our HF Welded Tube Mills are designed for durablility and usability

Custom engineered to meet your specific product requirements

Below are the standard models for our tube mill systems

| Model Number | Tube Size Range | Wall Thickness |

|---|---|---|

| AM-1500X-HF | .375" - 1.750" Dia. | .020" - .083" |

| AM-2000-HF | .500" - 2.250" Dia. | .025" - .125" |

| AM-2500-HF | .750" - 3.000" Dia. | .030" - .160" |

| AM-3000-HF | 1.000" - 4.000" Dia. | .040" - .200" |

| AM-4000-HF | 1.250" - 5.000" Dia. | .050" - .250" |

| AM-4500-HF | 1.500" - 5.500" Dia. | .060" - .300" |

| AM-5000-HF | 1.750" - 6.000" Dia. | .075" - .335" |