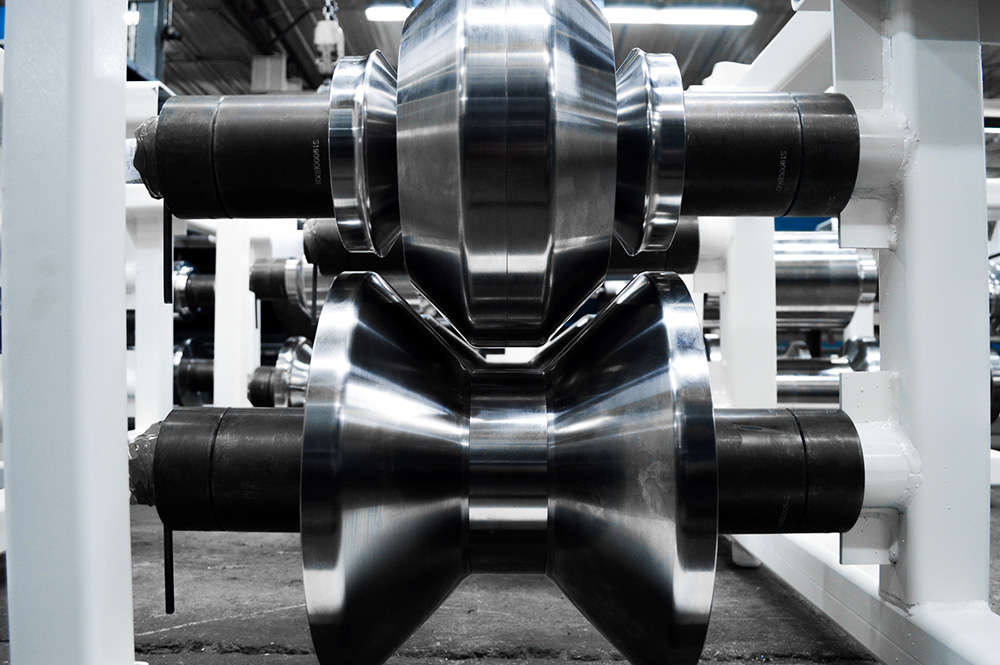

Addison Machine Engineering's experienced staff of mechanical engineers will custom design roll form roll tooling to meet your specific needs. Addison Machine Engineering's field service includes installation of all new rolls and equipment, as well as technical training regarding proper mill operation and maintenance for all necessary customer personnel.