We partner with tube & pipe manufacturers to design and engineer custom TIG Welded Tube Mill Systems for their specific product requirements. We belive if our customer is successful, we are successful. Success comes from having a strong partnership.

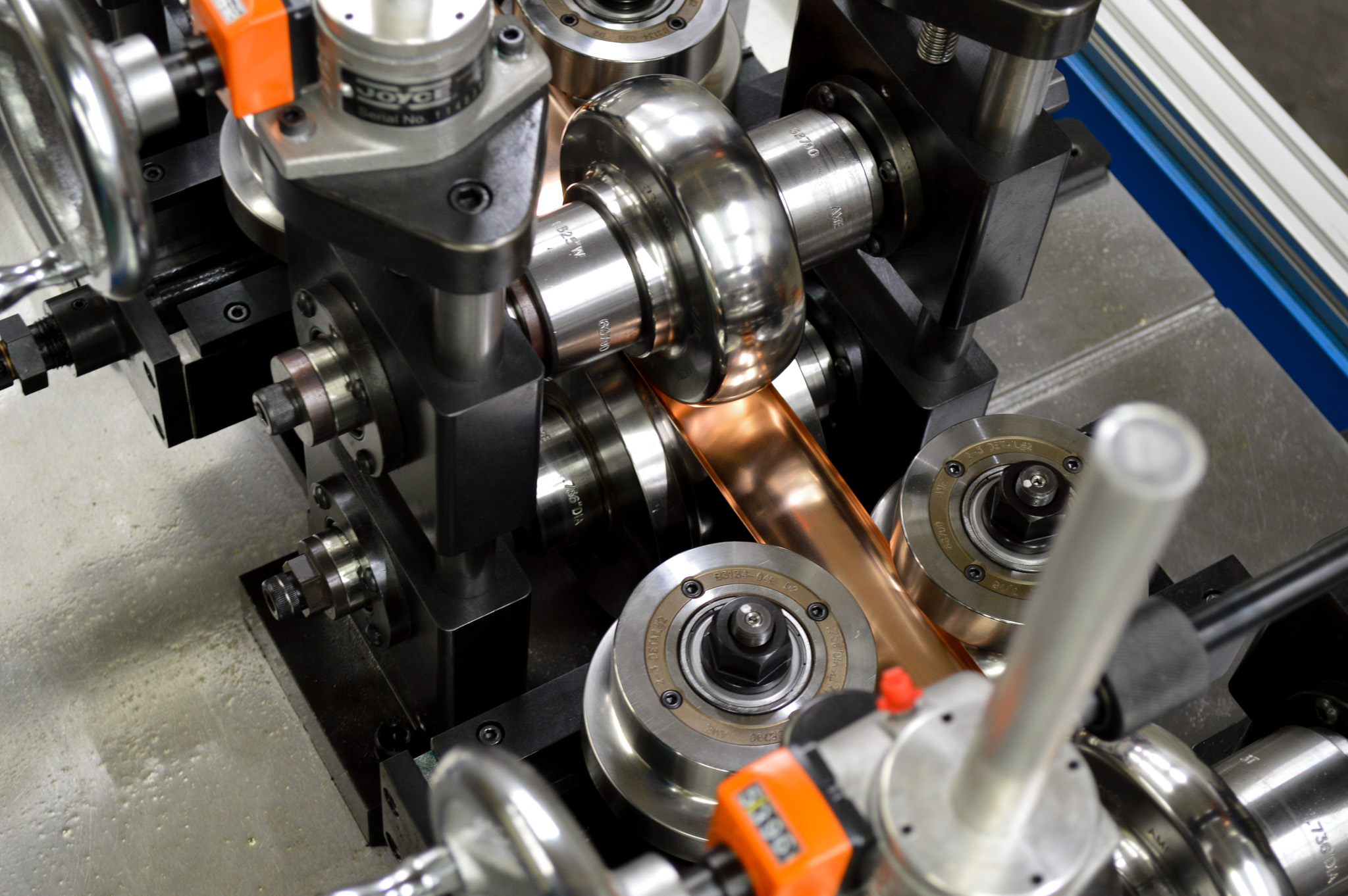

Our TIG Welded Tube Mills are designed for durablility and usability

Custom engineered to meet your specific product requirements

Below are the standard models for our tube mill systems

| Model Number | Tube Size Range | Wall Thickness |

|---|---|---|

| AM-0750-TW | .125" - .500" Dia. | .007" - .035" |

| AM-1000-TW | .188" - .750" Dia. | .007" - .049" |

| AM-1500-TW | .250" - 1.500" Dia. | .015" - .065" |

| AM-1500X-TW | .375" - 1.750" Dia. | .020" - .083" |

| AM-2000-TW | .500" - 2.250" Dia. | .025" - .109" |

| AM-2500-TW | .750" - 3.000" Dia. | .030" - .125" |

| AM-3000-TW | 1.000" - 4.000" Dia. | .040" - .134" |